3个变速驱动器水泵给商业大楼保压供水的实现 点击:800 | 回复:16

<span style="font-family:SimSun">用</span>3<span style="font-family:SimSun">个变速驱动器水泵给商业大楼保压,因为不同时段的用水情况会大不相同,在晚上只要运行一个水泵就可以保压,而高峰期却必须用三个水泵才可以保压;自动控制系统要决定何时要启动或停止另外一个水泵并且在此过程中保持水压平稳。另外为了平衡水泵的使用,最优先运行的水泵是要循环轮流的,在轮换最优先运行水泵的过程中也要保持水压平稳。除这些正常运行转换外,还有些情况需要考虑,如最优先运行水泵故障,或某个水泵正处于检修中等.</span>

<font face="SimSun">下面就是我所用的控制逻辑并用解释语言实现。</font>

正在下载,请等待……

正在下载,请等待……

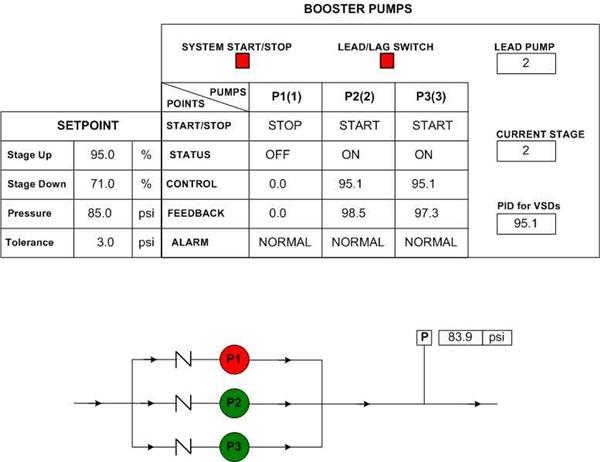

Define 3 pumps as P1, P2, and P3

Define priority pumps as Lead1, Lag2, and Lag3; initially Lead1 = P1, Lag2 = P2, and Lag3 = P3. Those 3 pumps’ priority will cyclic rotation.

Define 4 Stages as Stage0 means no pump runs, Stage1 means 1 pump runs, Stage2 means 2 pumps run, and Stage3 means 3 pumps run.

Have 4 setpoints:

Stage up-----percentage of VSD above which the ON pumps run for over period of time, then go up to next Stage.

Stage down-----percentage of VSD below which the ON pumps run for over period of time, then go down to next Stage.

Pressure----water pressure the system should maintain.

Tolerance----system allows the water pressure go to as low as to the setpoint minus tolerance, system only go up to next Stage when water pressure below setoints minus tolerance.

3 VSD driven pumps (P1, P2, P3) to maintain pressure

1. Lead/Lag arrangement, arrange 3 pumps as Lead1, Lag2, and Lag3

A. Lead1 (= P1), Lag2 (=P2), Lag3 (=P3)

B. Lead/lag rotation: Lag3→Lag2, Lag2→Lead1, Lead1→Lag3

i. On specific time daily

ii. Operator rotate lead/lag as requested

iii. Lead pump failed to operate

2. Stages

A. Stage0 for no pump ON when system shut down or they are all out of service

B. Stage1 for one pump ON to maintain water pressure

C. Stage2 for two pumps ON to maintain water pressure

D. Stage3 for three pumps ON to maintain water pressure

3. Put Pumps to “Out of Service” or Maintenance

A. Pumps in “Out of Service” will be out of Lead/Lag rotation

B. Stages will limit to number of good pumps

C. Reorder good pumps

4. Stages go up transfer ( not allow lead/lag transit)

A. Once Lead1 run above 'Stage up’but not during lead/lag transition and still could not maintain pressure for 2 minutes, Stage go up one level if it is lower than maximum Stage with current good pumps.

B. Start next available lag pump, slowly ramp up speed of new started pump; and PID control to operate other ON pumps to maintain pressure.

C. Once speed of new started pump get higher than speed of other pumps minus 1, finish stages go up transfer.

D. All ON pumps run at the same speed

5. Stages come down with or with out Lead/Lag transit

A. Once all ON pumps run at speed lower than ’Stage down’ but not during Lead/Lag transit and pressure still maintained for more than 2 minutes, Stage come down one level if it is higher than Stage1.

B. When Stage coming down, the speed of the last lag pump slowly ramp down when there is no Lead/Lag transit; or ramp down the speed of the old Lead pump when Lead/Lag transit. PID control to operate new Lead pump and other ON Lag pumps.

C. Turned off last Lag or old Lead Pump when its speed is ramped down to 20%

D. Complete stage come down transit and Every ON pumps run at same speed.

6. Transit Lead/Lag when Stage not change

A. Once Stage is equal to number of Good pumps, that means all pumps are already ON, just simply rotate the list of Lead/Lag.

B. If Stage is lower than number of good pumps, start next available lag pump and slowly ramp up its speed, and at the same time, PID control to operate pre-ON pumps; once the speed of new started pump is higher than old Lead pump, slowly ramp down the speed of old Lead pump, PID control to operate the rest ON pumps.

C. Turn off old Lead pump once its speed down to 20%.

D. Complete Lead/Lag transition and all ON pumps run at same speed .

7. Lead/Lag transit required during Stage go up

A. Set Lead/Lag to be change mark

B. Wait for stage going up transfer to be finished

C. Do Lead/Lag transit after complete Stage go up transfer

回复内容:

对:James Yang 3 VSD driven pumps (P1, P2, P3) to maintain pressure 1. Lead/Lag arrangement, arrange 3 pumps as Lead1, Lag2, and Lag3A. Lead1 (= P1), Lag2 (=P2), Lag3 (=P3)B. Lead/lag rotation: Lag3→Lag2, Lag2→Lead1, Lead1→Lag3 i. On specific time daily ii. Operator rotate lead/lag as requested iii. Lead pump failed to operate2. StagesA. Stage0 for no pump ON when system shut down or they are all out of serviceB. Stage1 for one pump ON to maintain water pressureC. Stage2 for two pumps ON to maintain water pressureD. Stage3 for three pumps ON to maintain water pressure3. Put Pumps to “Out of Service” or MaintenanceA. Pumps in “Out of Service” will be out of Lead/Lag rotationB. Stages will limit to number of good pumpsC. Reorder good pumps4. Stages go up transfer ( not allow lead/lag transit)A. Once Lead1 run above 'Stage up’but not during lead/lag transition and still could not maintain pressure for 2 minutes, Stage go up one level if it is lower than maximum Stage with current good pumps.B. Start next available lag pump, slowly ramp up speed of new started pump; and PID control to operate other ON pumps to maintain pressure.C. Once speed of new started pump get higher than speed of other pumps minus 1, finish stages go up transfer.D. All ON pumps run at the same speed5. Stages come down with or with out Lead/Lag transitA. Once all ON pumps run at speed lower than ’Stage down’ but not during Lead/Lag transit and pressure still maintained for more than 2 minutes, Stage come down one level if it is higher than Stage1.B. When Stage coming down, the speed of the last lag pump slowly ramp down when there is no Lead/Lag transit; or ramp down the speed of the old Lead pump when Lead/Lag transit. PID control to operate new Lead pump and other ON Lag pumps.C. Turned off last Lag or old Lead Pump when its speed is ramped down to 20%D. Complete stage come down transit and Every ON pumps run at same speed.6. Transit Lead/Lag when Stage not changeA. Once Stage is equal to number of Good pumps, that means all pumps are already ON, just simply rotate the list of Lead/Lag.B. If Stage is lower than number of good pumps, start next available lag pump and slowly ramp up its speed, and at the same time, PID control to operate pre-ON pumps; once the speed of new started pump is higher than old Lead pump, slowly ramp down the speed of old Lead pump, PID control to operate the rest ON pumps.C. Turn off old Lead pump once its speed down to 20%.D. Complete Lead/Lag transition and all ON pumps run at same speed .7. Lead/Lag transit required during Stage go upA. Set Lead/Lag to be change markB. Wait for stage going up transfer to be finishedC. Do Lead/Lag transit after complete Stage go up transfer 内容的回复:用的是什么语言?

- 技术文章—特快瞬态过电压VFT...

[896]

[896] - 许永硕:三种工业PaaS平台方向...

[1967]

[1967] - KUKASimpro软件使用问题

[1281]

[1281] - 图说智能----自动化产业必备...

[669]

[669] - 许永硕:戴尔的零库存为什么这...

[924]

[924] - 最近在了解C#开发opc采集ABp...

[883]

[883] - 智能化时代的到来,会不会导致...

[2096]

[2096] - 钢结构厂房柱子加固方法及注...

[1289]

[1289] - 工业线阵相机如何在编码器的...

[6059]

[6059] - 三菱PLC控制松下伺服X4接线

[3537]

[3537]

官方公众号

智造工程师

-

客服

客服

-

小程序

小程序

-

公众号

公众号

工控网智造工程师好文精选

工控网智造工程师好文精选