用作热电偶保护管的高温抗氧化合金介绍 点击:295 | 回复:0

热电偶厂家用于生产测量高温的热电偶保护管材料有GH3030、GH3039、GH140、Inconel 600、3YC52、HR1300等,本贴介绍这些高温抗氧化合金材料的性能和力学性能。

原文地址:yunrun.com.cn/tech/1595.html

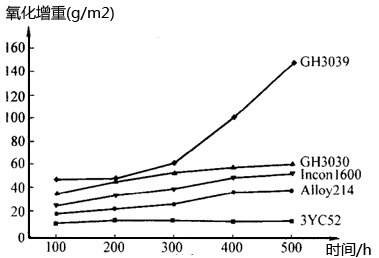

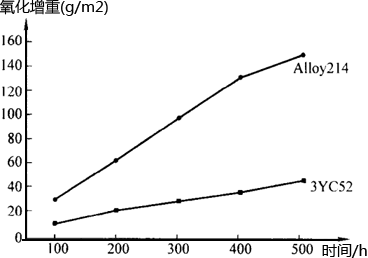

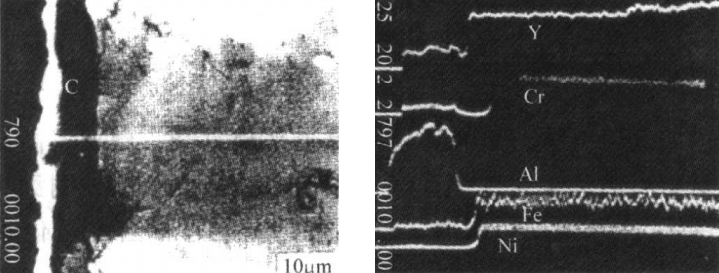

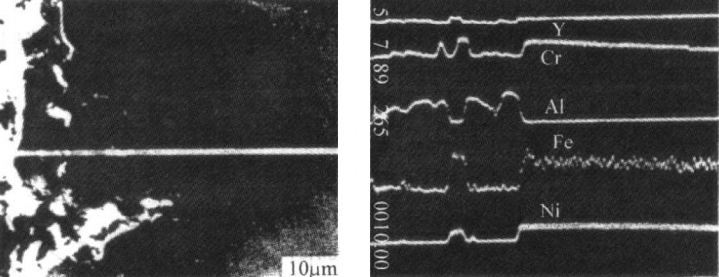

金属材料的抗高温氧化腐蚀性能主要是靠在高温下形成致密的保护膜来实现,保护膜既可阻止氧、硫等腐蚀性气体向基体中扩散,又能阻止金属离子向外扩散。常用的保护膜主要有Cr2O3和Al2O3等。当使用温度高于1100-115-℃时,Cr2O3剥落严重,因此,该种高温合金短期最高使用温度应低于1200℃。典型高温耐热合金有GH3030、GH3039、GH140、Inconel 600、3YC52等,各个仪表厂家常用这些合金材料生产特殊用途的热电偶。Al2O3保护层具有比Cr2O3更佳的抗氧化能力。当温度高达1200-1300℃,Al2O3保护层仍不易剥落,且形成Al2O3所需的平衡氧分压明显低于Cr2O3的分压。如Fe-Cr-Al电热合金含有高达5%-8%(质量分数)的Al,能在高温形成单一Al2O3保护层,从而具有优异的抗氧化腐蚀性能。可是这样合计为铁素基体,脆性很大,高温强度低,限制了其应用。为了提高合金在1200-1300℃的抗氧化性能,开发出一些高温下能形成Al2O3的高温合金,国外典型合金有Haynes Alloy 214、эп747、Inconel 602、Inconel 603等。重庆仪表材料研究所在国外合金基础上,通过提高Cr、Al含量,并采用晶界精华和强化技术,研制出一种新型抗氧化高温耐热合金3YC52,其主要原因是在高温下除形成Al2O3、Cr2O3的混合氧化膜外,还能形成致密、单一α-Al2O3保护膜。3YC52合金与国外同类合金在1100℃、1300℃抗氧化性能对比(见图1和图2)和氧化层的SEM和EPMA分(见图3和图4)。

图1 3YC52与同类合金1100℃高温氧化曲线

图2 3YC52与同类合金1300℃高温氧化曲线

图3 1300℃/500h下3YC52氧化层的SEM和EPMA分析

图4 1300℃/500h下Alloy 214氧化层的SEM和EPMA分析

上述合金材料的研制成功,解决了高温环境中许多材料难题。但是在使用中发现上述材料出现变形问题。因此,如何能在保持高温氧化性能基础上,提高合金的高温强度,成为抗氧化合金技术进步的关键。技术人员在3YC52基础上,对材料和合金进行了重新设计,同时采用原位反应颗粒增强新技术,研制出能在高达1250-1350℃的温度下长期使用的氧化耐热合金HR1300。HR1300高温强度较国外同类合金提高30%以上。可用于各种氧化剂氧化腐蚀环境下使用的热电偶保护管、高温管道和高温静止件等。国内外常见高温耐热合金力学性能见表1。

表1 国内外常见高温耐热合金力学性能

高温合金材料 温度 抗拉强度σb/MPa 屈服强度σ0.2/MPa 延伸率δ(%)

HR1230 20℃ 866 390 48

980℃ 242 145 83

1100℃ 135 70 82

1200℃ 65 34 105

HR1300 20℃ 680 340 45

980℃ 120 80 85

1100℃ 70 45 95

1200℃ 35 20 102

3YC52 20℃ 650 358 55

980℃ 65 40 126

1100℃ 40 25 132

1200℃ 25 15 125

Alloy 214 20℃ 958 565 43

980℃ 115 58 83

1100℃ 60 29 83

1200℃ 30 10 109

эп747 20℃ 600 300 50

980℃ 50 35 45

1100℃ 30 20 70

1200℃ 20 — 90

Inconel 800H 20℃ 566 245 49

980℃ 76 56 100

1100℃ 35 23 108

1200℃ — — —

Inconel 601 20℃ 704 241 50

980℃ 90 74 100

1100℃ 45 41 120

1200℃ 35 13 121

Inconel 600 20℃ 662 282 45

980℃ 76 42 115

1100℃ 36 21 120

1200℃ — — —

GH3030 20℃ 756 355 41

980℃ 70 — 50

1100℃ 43 — 71

1200℃ 27 — 108

GH3039 20℃ 820 — 46

980℃ — — 95

1100℃ — — —

1200℃ — — —

在特殊场合使用的热电偶使用寿命跟热电偶保护管材料有非常大的关系,每一种材料都需要在不同使用工况经实际应用验证后才能定型与热电偶生产中。

- 恒液位PID控制遇到的问题

[968]

[968] - 详谈减压塔浮球液位计的测量...

[553]

[553] - GCMS开关机都是有技巧的,搞乱...

[1243]

[1243] - E+H涡街流量计常出现的故障

[702]

[702] - 双法兰差压变送器零点迁移计...

[974]

[974] - 开关电源的输出端对地电压的...

[1863]

[1863] - 从电气角度理解PID

[2440]

[2440] - 旋转变压器检验有哪些要求?

[687]

[687] - ABB电磁流量计电源板故障解析...

[1754]

[1754] - 绝压变送器如何校准?

[1053]

[1053]

官方公众号

智造工程师

-

客服

客服

-

小程序

小程序

-

公众号

公众号

工控网智造工程师好文精选

工控网智造工程师好文精选